IBC SOLAR - Your Solar Energy Solutions Provider

Reliable, competent and with above-average yields.

From individual solar modules to entire solar parks: Solar energy from one of the world’s most experienced solar solutions providers.

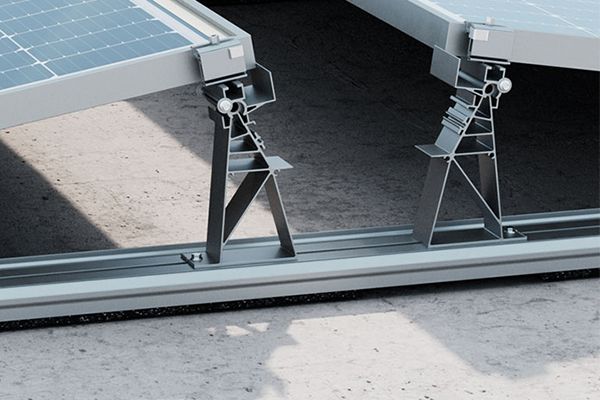

IBC AeroFix G3

Maximum flexibility!

The further development of our flat roof mounting system means that it is now highly flexible on all roofs and can be installed quickly and easily - with no roof penetration.

Our Product Catalogue

Quickly find the right products for your solar needs

Our product catalogue contains more than 1,500 articles. High-quality solar modules, inverters, accessories and powerful storage solutions. Browse through quickly and easily.

Our Training Programmes

Your 24/7 training partner for photovoltaics

Whether a PV installer or new employee, architect or sales professional or simply interested in photovoltaics. We offer a combined training approach with a mixture of face-to-face training and online events.

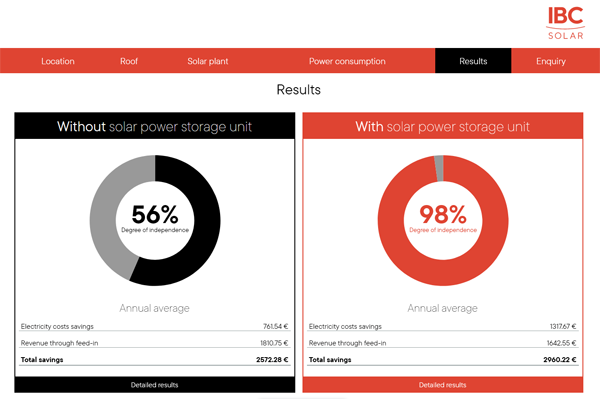

Our Power Calculator

Calculate the benefits of a solar roof!

Find out how much solar power your roof-mounted system can produce in a year, what share of the electricity you will be able to use yourself, and how this will help you lower your energy costs.

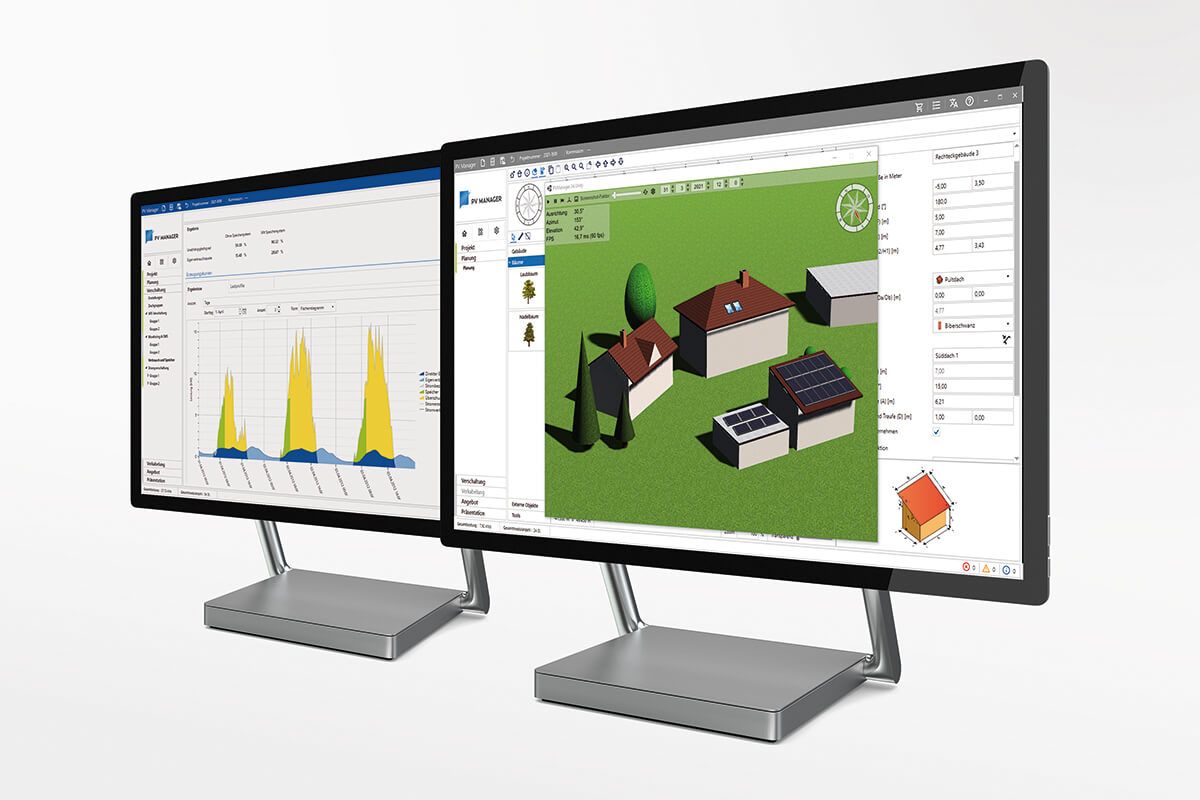

PV Manager

Plan faster than you can imagine

The most powerful planning tool on the market gives you more time for your customers. PV Manager is a planning tool for grid-connected PV systems for both residential & commercial sectors.

Our Quality Promise

Quality is our top priority

The SUNLAB PV test laboratory was recently expanded with a load test table for both static mechanical and dynamic testing. Please click on the link below to download our quality brochure now.

Blog

Visit our IBC SOLAR Blog!

IBC SOLAR colleagues from our various departments write about the photovoltaic market, our latest projects and company news.

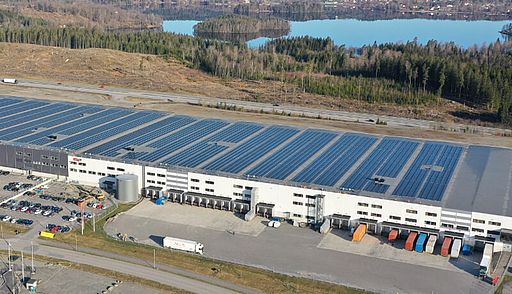

IBC SOLAR offers tailor-made solar energy solutions

IBC SOLAR offers tailor-made solutions ranging from individual solar panels to complete PV systems. For more than 40 years, IBC SOLAR has continually shaped the development of solar energy as a source of regenerative energy. This German company with its traditional background is one of the pioneers in the field of solar technology and one of the international leaders in the field of energy production from sunlight. IBC SOLAR is a complete solar energy system provider that offers everything from consulting to maintenance under one roof. Whether supplying self-consumption systems to the commercial sector, private households that generate their own electricity via a complete photovoltaic system, or even entire solar parks. IBC SOLAR can help develop a tailor-made, personalized concept that fits your needs and energy requirements while considering localized conditions.

Photovoltaics – the future of solar energy generation

The idea of converting solar energy into usable energy from a solar cell with the help of semiconductors has changed our world. Photovoltaics gives us the opportunity to say goodbye to energy from dwindling supplies of fossil fuels. Get an experienced partner such as IBC SOLAR on your side, if you want to take a responsible step into the future with your company or private household by switching to renewable energies, and at the same time saving noticeably on your energy costs.

Since 1982, we have been committed to making solar energy a real alternative to conventional power generation. We are proud to provide products which helps supply solar power to over three million people a year, with more than 6 GW of installed capacity. We work together with more than 1,000 specialist partners worldwide, from solar engineers to electrical contractors to the roofer. Together we also develop reliable photovoltaic systems with or without solar power storage!

IBC SOLAR provides solar modules of the highest quality

From planning to fulfilment of photovoltaic systems, IBC SOLAR and its specialist partners offer competent customer service. The highest quality of individual components, especially solar modules, is at the forefront of our business. The type of solar module must be chosen to suit specific circumstances - decisive factors include the load capacity of the roof, wind load, snow load regions, salt water resistance, the size of the roof surface, the roof pitch and the desired efficiency. In addition, IBC SOLAR places great importance to ensure that every solar module delivers with its efficiency and longevity. For our solar systems we give you our quality promise. Thanks to our strict production standards, we deliver systems and solutions of the highest standard. To help maintain this, we conduct regular internal controls and also go through independent certifications and examinations. Our well thought-out systems consist of high-quality individual parts that are optimally paired with each other. Photovoltaic systems from IBC SOLAR are reliable and provide maximum yields. We build solar systems that work optimally for more than twenty years and achieve energy cost savings of up to 80 percent (with electricity storage). And that's not all: take advantage of additional government compensation and feed the energy you do not use into the public grid. As a private individual you can make your solar system a sustainable investment.

At IBC SOLAR, one of the world's leading photovoltaic system providers, you will discover a comprehensive product range for both grid connected and off-grid solar energy solutions that you can rely on!